Applications

Serving a Wide Range of Industries

Sonobond Ultrasonics Inc. is a leading manufacturer and provider of ultrasonic machinery for cutting, welding and bonding metals, plastics, textiles and nonwovens. With over 150 patents, We offer technological expertise in applying our state-of-the-art systems and equipment for a wide range of industries, including apparel, automotive, appliance, electronic packaging, medical disposables, filtration and home furnishings.

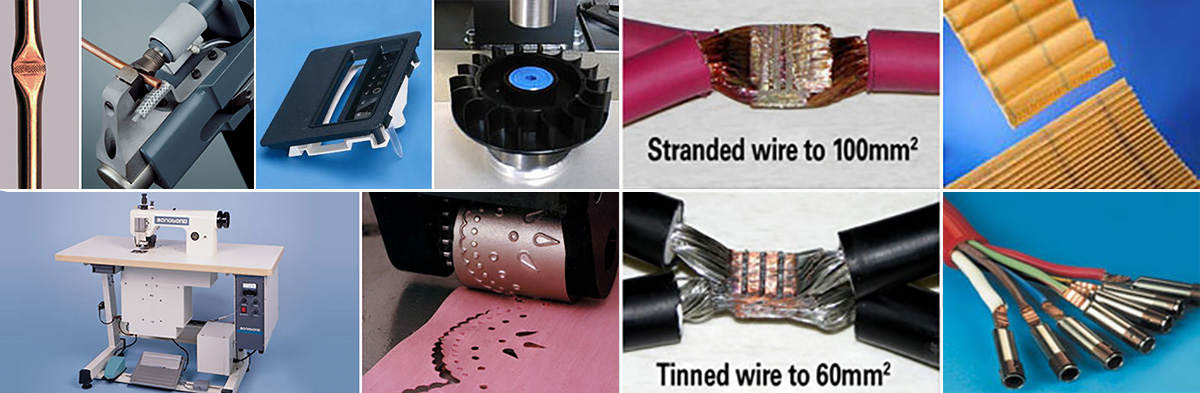

Our series of ultrasonic metal welders includes the most powerful spot welder in the industry, as well as the only ultrasonic welder that can join up to 10 stranded wires from a flat flexible circuit to multi-connection terminals in a single pulse.

The SeamMaster line of continuous ultrasonic bonding equipment for textiles and nonwovens cuts and seals in one pass without the use of consumables. It includes a model designed for manual feeding; a table-mounted model; a specialized unit with a programmable flying cutter; and a machine builder’s module for integration into production lines.

Sonobond serves the plastics industry with our family of SureWeld ultrasonic plastic bonding units including 20, 35, and 70 kHz bench models and hand-held units, as well as modular units for automated assembly, and a space-saving integrated welder with the power supply built into the welding head.

Used in a Wide Variety of Applications

Sonobond’s ultrasonic machinery is used by companies around the world. Its state-of-the-art product line includes the following:

- SonoWeld® Ultrasonic Metal Spot Welder for non-ferrous similar or dissimilar metal spot welds, wire-to-terminal welds, unique welding of tin-coated metals, aluminum welding, and battery assembly.

- Dual Head Ultrasonic Metal Spot Welder, with two welding heads for increased welding capacity, for welding non-ferrous sheet metal and aluminum up to 3mm thick, unique welding of tin-coated metals.

- SpliceRite™ Wire Splicer for fast, efficient wire harness assembly.

- Dual Head SpliceRite™ Wire Welder, with two welding heads for increased welding capacity, for welding copper wire bundles up to 100 sq. mm cross sectional area, and unique welding of tin-coated wire bundles up to 60 sq. mm. cross sectional area.

- WeldMaster™ Ultrasonic Spot Welder for superior spot welding.

- SeamMaster® Ultrasonic Bonding Machine line for bonding synthetics and nonwovens – a process that cuts, “sews,” and seals in just one pass – creating leak-proof seams that are strong and regulatory-compliant.

- LaceMaster™, PlungeBonder™, and RingMaster™ Textile Bonders for superior assembly of filters, medical and PPE fabric items, hazmat gear and body armor components.

- Photovoltaic (PV) Modular System for welding interconnects on solar panels.

- SureWeld™ Ultrasonic Plastic Bonding Machines – including an optional microprocessor-controlled power supply that can be attached or mounted separately.

You can purchase, rent, or lease Sonobond ultrasonic welders and bonders as stand-alone units or as modular systems for integration into your production line or custom equipment.

Sonobond ultrasonic equipment is used by leading manufacturers in the automotive, appliance, filtration, HVAC, apparel, aerospace, medical, electronic, electrical and ballistic vests/body armor fields. All machinery is dependable, environmentally friendly and easy to operate.

Call 1-800-323-1269 to see if your application can be improved using Sonobond’s ultrasonic bonding technology.