Battery Assembly Solutions

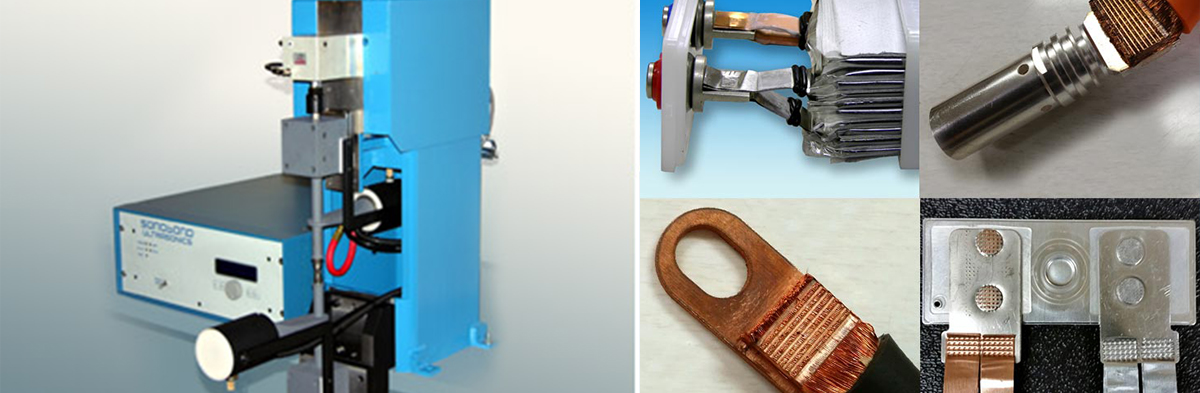

Our Welders are Uniquely Positioned to Meet Increased Demand for High Power Electric Vehicle Batteries and Charging Stations

Sonobond’s metal welders can add eco-friendly, dependable, cost-effective performance to your manufacturing operation.

Using our patented Wedge-Reed System – with no external heat, current or fillers – our units create solid-state, highly conductive welds, eliminating metallurgical defects such as porosity and intermetallics that commonly exist in fusion welds.

This System also welds tinned and oxidized metals – a unique ability unmatched by any other ultrasonic system.

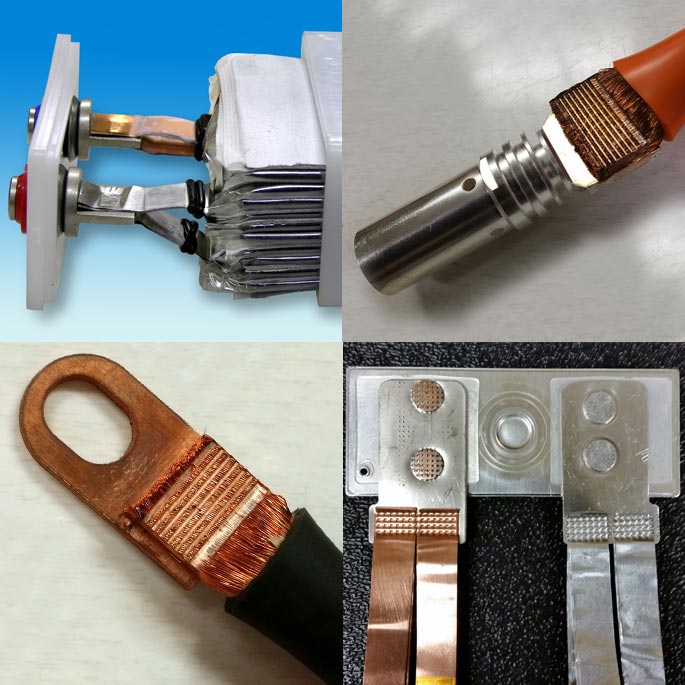

Dual-Head Systems for Advanced Storage Capacity Batteries

Our welders quickly and reliably weld multiple anode and cathode foils to battery tabs and terminals, as well as stranded copper wires to terminals. Our dual-head welding and splicing systems accommodate the larger wire bundles and terminals required for rechargeable batteries that must have high power and high storage capacities.

Sonobond’s Dual Head Spot Welder is the first ultrasonic model to join up to 100 layers of copper or aluminum foil in just one pulse without tearing the foils – even if they’re as thin as seven microns. And our Dual Head Wire Splicer welds stranded copper wire bundles up to 100 sq.mm cross sectional area.

Order Our Free Ultrasonic Welding Viability Test

Check out our equipment today and try our free, no-obligation Ultrasonic Welding Viability Test to see how our welders work with your materials to meet your specific applications and requirements. Just click on the button in the right column.

Advancing Ultrasonic Assembly Solutions

For more than 60 years, Sonobond’s proven technology, well-established quality standards and industry acceptance have made it a leading manufacturer of innovative ultrasonic welding and bonding equipment for a wide variety of applications.

Typical Assembly Applications

- Spot welding

- Wire-to-terminal welding

- Wire-to-wire welding

- Tabs for battery cells

- Thin aluminum or copper foil to battery tabs

- Bus bars

- Lithium-ion battery terminals

- Foil-wound capacitors

- Thin aluminum or copper foil

- Electrical contacts

- Electrical wire harnesses

- Fuses/circuit breakers

- Ignition modules

- Starter motors

- PV panel interconnects

- HVAC tubing