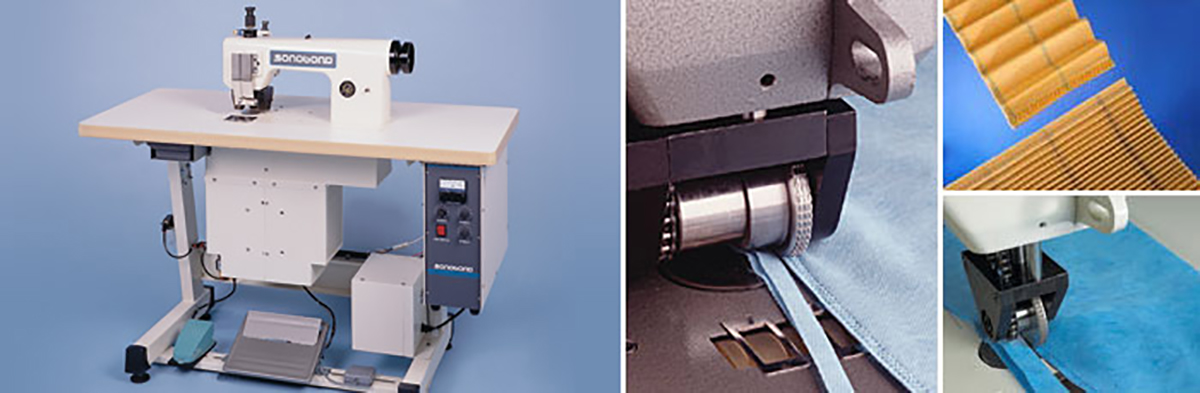

SeamMaster® Ultrasonic Sewing Machine

Sonobond’s SeamMaster® Ultrasonic Bonders cleanly cut and seal the edge of synthetic films and fabrics in just one pass without using consumables such as thread or adhesives. Fraying and unraveling are totally eliminated along the sealed edge as a double layer of fabric passes under the SeamMaster to automatically join the two layers as they are slit and sealed. These cutter/sealers operate at speeds much faster than sewing or adhesive machines. Yet they require minimal retraining of sewing machine operators.

Features

- Versatile, general purpose machine works just like a traditional sewing machine

- Cuts, “sews” and trims in one pass

- Available in variety of stitch patterns

- Applications: Medical disposables, filters, protective products, and thin film packaging

- Operates without the use of thread, glue or other consumables