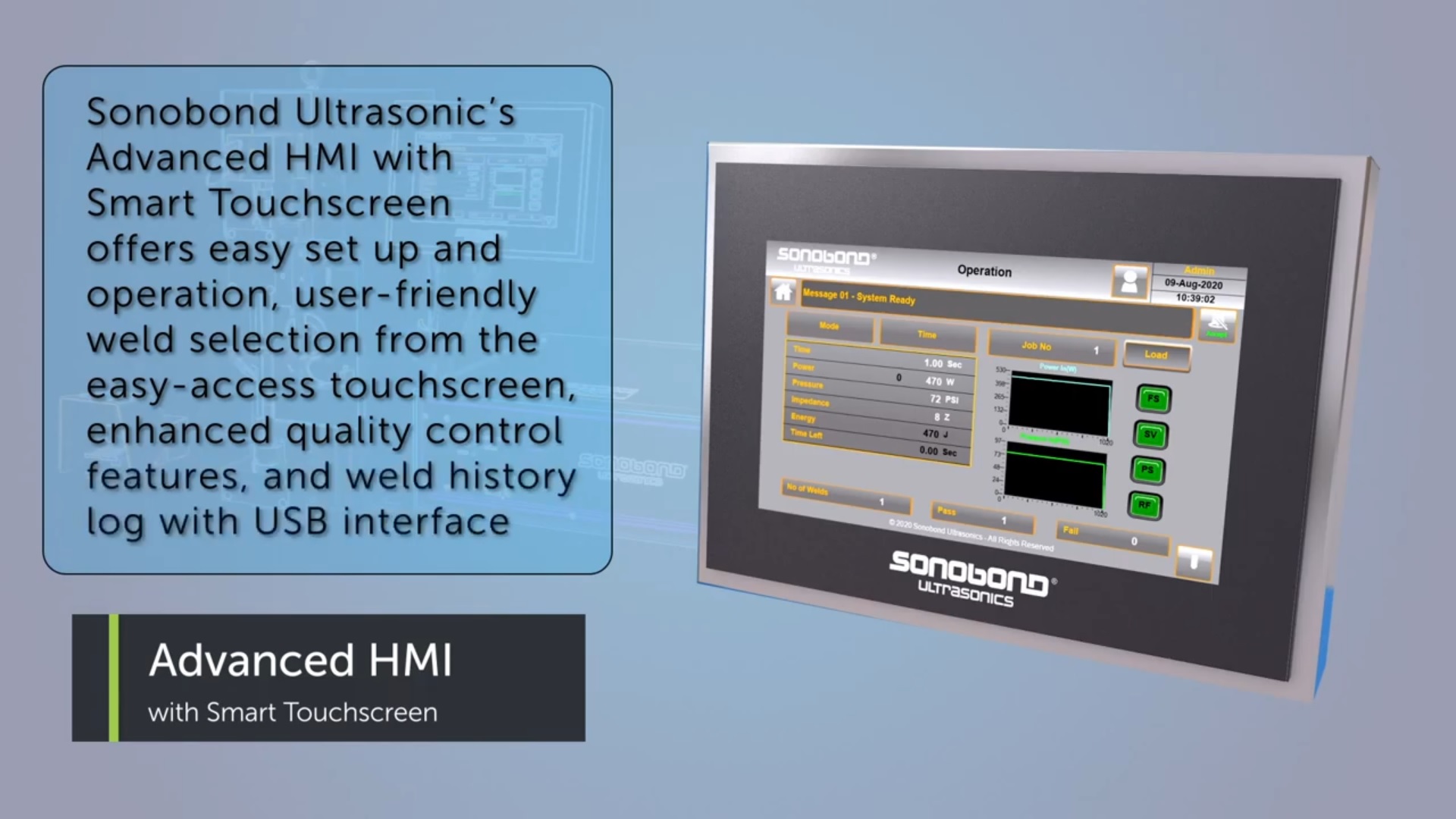

Advanced HMI with Smart Touchscreen

Sonobond Ultrasonics’ Advanced Human-Machine Interface with Smart Touchscreen offers easy set up and operation, user-friendly weld selection from the easy-access touchscreen, enhanced quality control features.

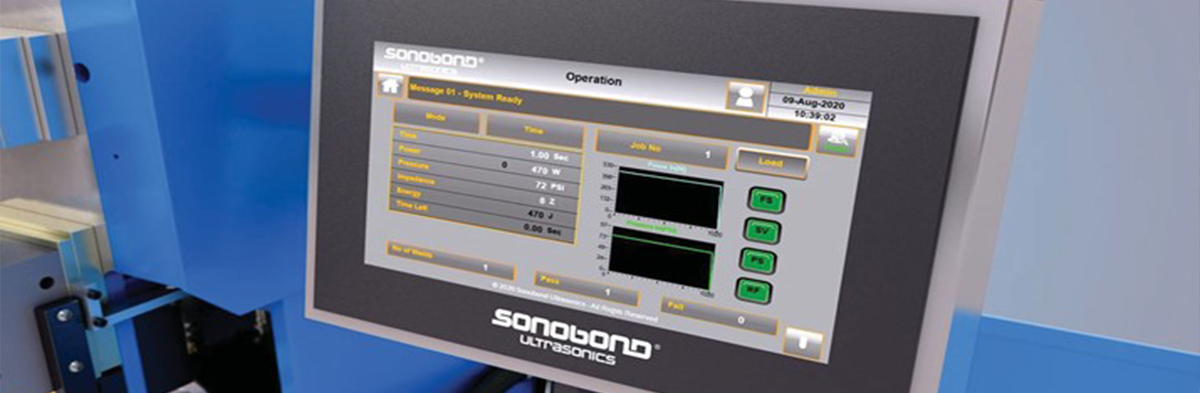

The HMI allows operators to customize four weld modes: time, energy, height and height with energy. It also supports the ability to run multiple jobs consecutively, reducing overall loading time. In addition, the HMI provides feedback on weld results, displays graphs showing pressure and power ranges, gives access to system settings and more. It can store up to 1,000 welds and export data to a USB drive for easy analysis.

The HMI with Smart Touchscreen can easily be incorporated into any Sonobond American-made ultrasonic metal welders, including the SonoWeld® Spot Welder, the Dual Head Metal Spot Welder, SpliceRite™ and Dual Head SpliceRite™ Wire Splicers, and the Single Point Ground Welder.

Features

Advanced HMI with Smart Touchscreen adds unparalleled, multi-function features to new or existing Sonobond Ultrasonic Metal Spot Welders and Ultrasonic Metal Wire Welders:

- Easy set up and operation, with on-screen help files,

- User-friendly weld selection from the easy-access touchscreen,

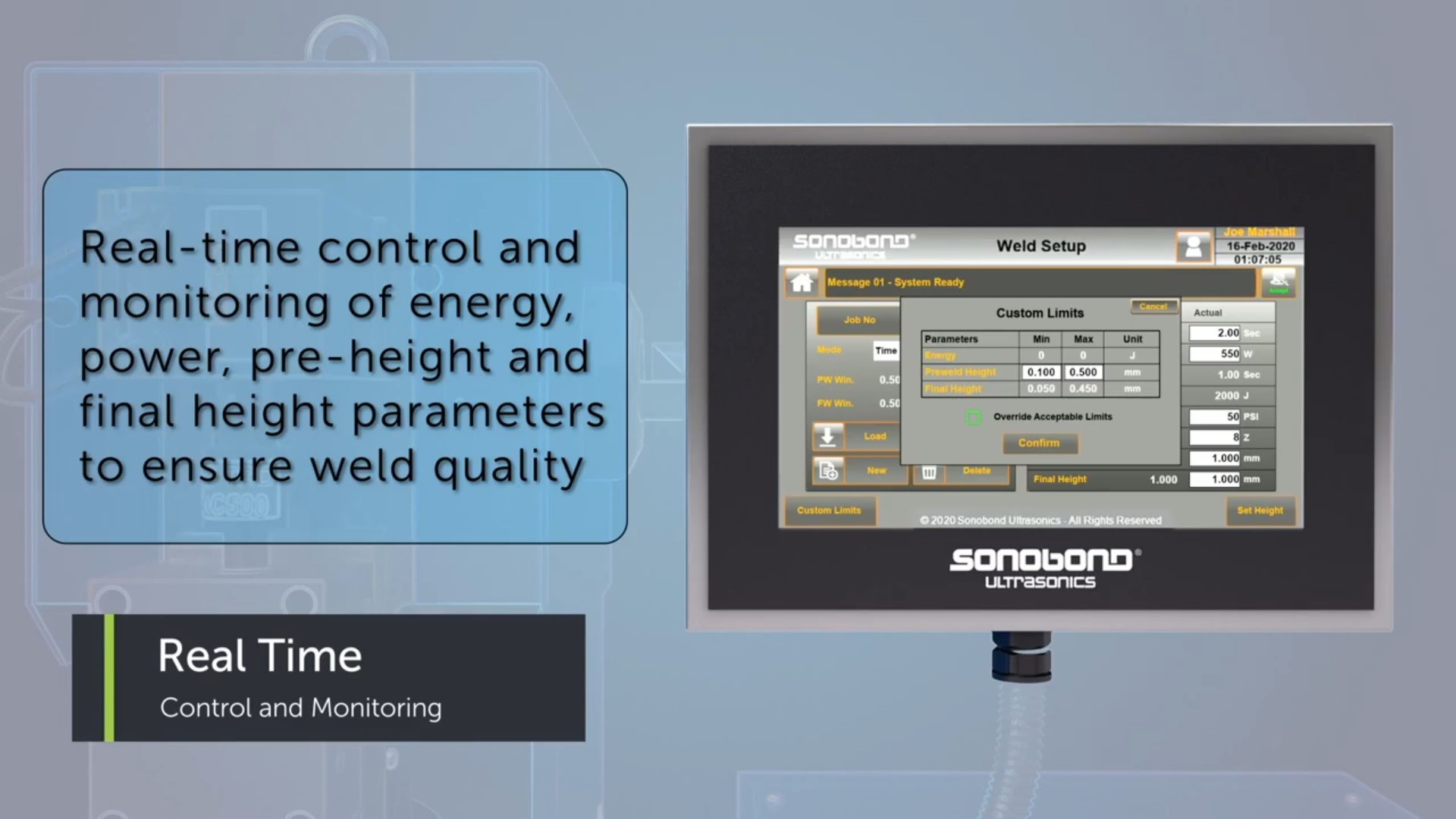

- Superior quality control capabilities, using real-time monitoring of weld parameters

- Weld history log of last 1000 welds can be exported via USB port for analysis and trending projections

- Four welding modes: time, energy, height, and height with energy,

- Sequence job selections to run multiple, separate jobs consecutively without needing to load a new job between welds

- Enhanced security features, including multiple access levels, alarm and shutdown after three consecutive failed welds, on-screen manuals, and maintenance alerts.