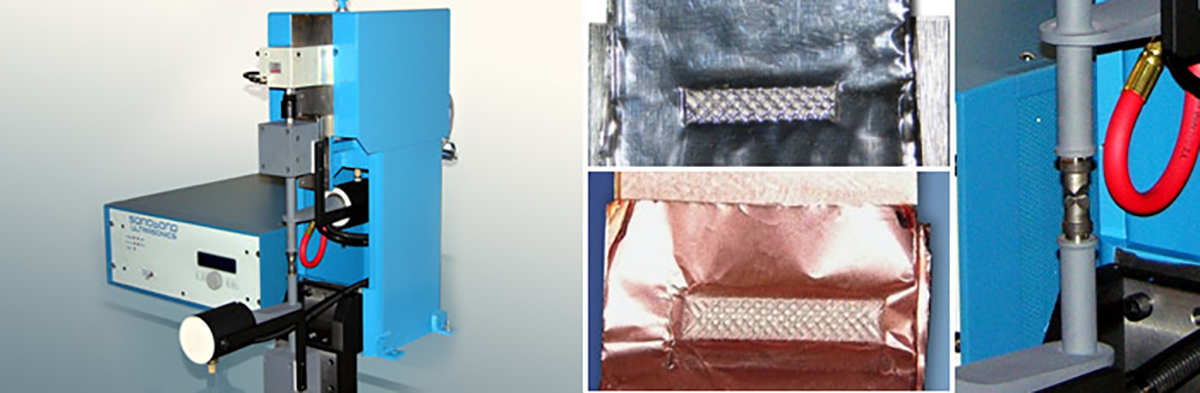

Dual Head Ultrasonic Metal Spot Welder

The Dual Head Ultrasonic Metal Spot Welder is capable of welding aluminum sheets up to 3mm thick, as used for automotive applications, and for welding up to 100 layers of delicate foils to battery tabs and terminals for lithium-ion and NiMH batteries. It uniquely welds even lightly tinned or oxidized metals in just a single pulse.

It easily welds large wire bundles to HV terminals for batteries used in the high-power, high-capacity energy storage industry.

The Dual Head uses our patented Wedge-Reed System, and an easily removable and replaceable tool steel Taper Lock Tip. Sonobond also custom-designs tooling to meet each customer’s specific needs.

Click here for information on our Advanced HMI with Smart Touchscreen

Features

- Features two ultrasonic welding heads, one on either side of the welding area, for increased welding capacity

- Welds non-ferrous sheet metal, including aluminum up to 3mm thick, and reduces tip sticking on thinner aluminum as used for automotive applications

- Welds up to 100 layers of anode and cathode foils – as thin as seven microns – without tearing – to battery tabs and terminals for lithium-ion and NiMH batteries. These batteries are used in electric vehicles, charging stations, and high-capacity energy storage batteries.

- Uniquely joins metals that are oxidized or lightly tinned – in just one pulse and without pre-cleaning – using our exclusive, patented Wedge-Reed System

- Creates a solid-state metallurgical bond with high conductivity and without producing arcs, sparks or fumes, or melting at the weldment.

- Microprocessor controller recalls up to 250 weld protocols, can weld by time, energy or height* and provides automatic frequency control and overload protection

- Uses Sonobond’s 3,500 watt power supply

* Pre-weld and post-weld height measurements are available when machine is equipped with our Advanced HMI